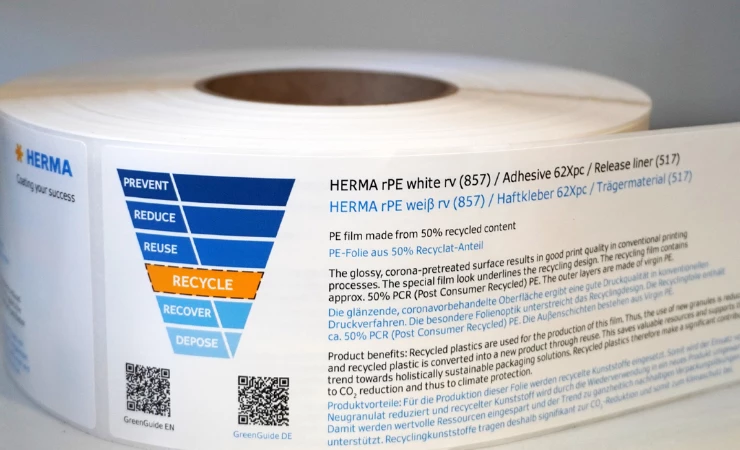

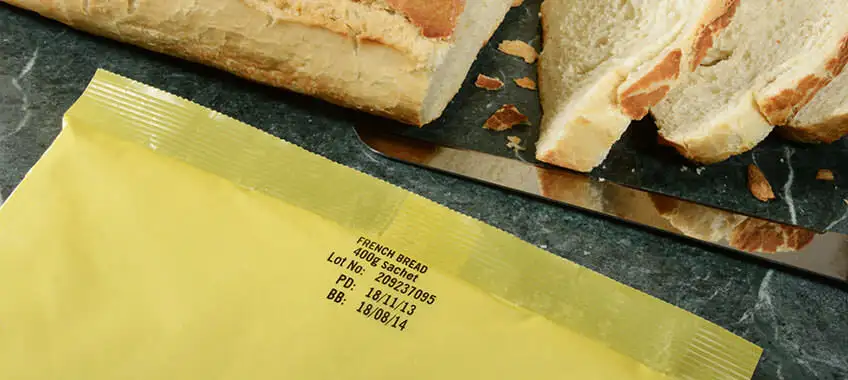

Supports applications requiring larger format variable data, such as allergen information, branding elements and complex regulatory content.

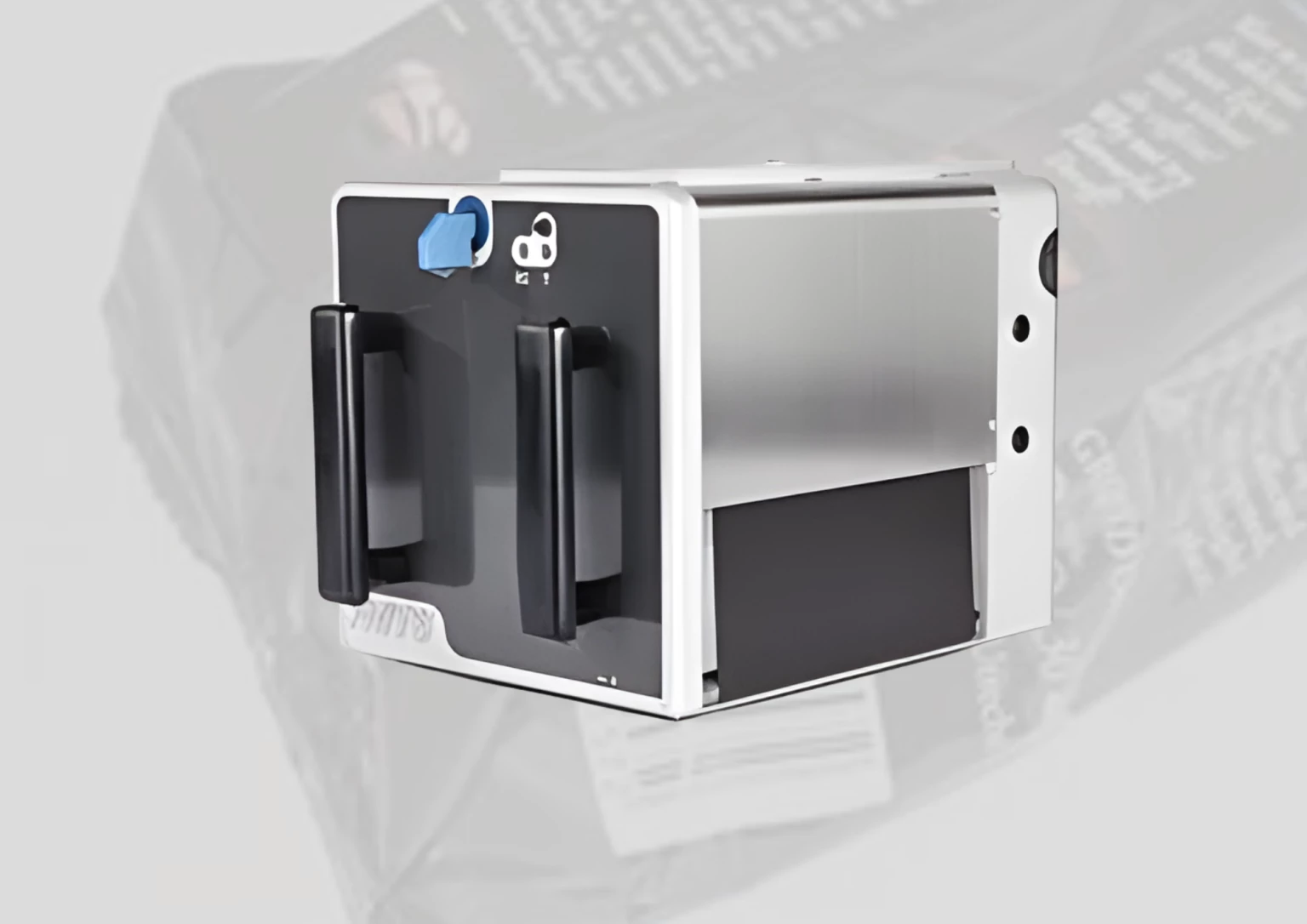

The Diagraph NGT6e Thermal Transfer Printer offers the NGT Series advantage of high speed printing with excellent print quality, featuring an extended intermittent print area of 160 × 155 mm, and continuous print area is 160x 1000 mm.