Premium Labellers

High performance labelling solutions combining precision engineering, smart control, and maximum flexibility for demanding production environments.

High performance labelling solutions combining precision engineering, smart control, and maximum flexibility for demanding production environments.

Servo Moto High Precision Wrap-Around Labelling

The HERMA 152C standard is a compact, high performance wrap-around labelling machine built for cylindrical products such as bottles, jars, tubes, and vials. Designed for precision and efficiency in limited production spaces, it ensures consistent labelling at speed. As part of the HERMA C Series, it combines modular flexibility with robust German engineering, supporting everything from simple wrap-around applications to advanced configurations with print and inspection systems.

With quick changeovers, many printing options and motorised unwinders, the 152C handles variations in product geometry without the need for change parts. The result: a smooth, reliable wrap-around process that delivers professional packaging quality every time.

Result Group supplies the HERMA 152C Standard fully configured to meet your line requirements. From integrated coding solutions to inspection for label accuracy and compliance, we deliver end-to-end reliability for your wrap-around applications. With local installation, training, service, and ongoing consumable management, we make sure your packaging line stays compliant, efficient, and retail ready.

No Change Part Required for One or Two Side Labelling.

The HERMA 362C is a compact yet robust side-labelling system designed for fast and accurate application on one or both sides of bottles, jars and containers. Engineered for maximum flexibility, it eliminates the need for change parts, allowing rapid product changeovers and minimising downtime in dynamic production environments.

A stabilising top belt ensures consistent product positioning throughout the labelling process, supporting high quality, repeatable results even at speed. Built on HERMA modular C Series platform, the 362C can be easily configured to suit a wide range of applications and production requirements. Optional printer integration enables batch coding, date marking, and traceability, making it a reliable solution for manufacturers seeking efficiency, precision, and adaptability in side labelling.

We customise the HERMA 362C to match your production layout, with local integration and service to ensure uptime and accuracy. Our long term support, including staff training and ongoing maintenance, keeps your packaging line efficient and future ready.

Apply labels with accuracy to irregular or recessed tops.

The HERMA 452C is a versatile top-labelling system designed to deliver precise label application, even on products with irregular, recessed, or uneven surfaces. Its adaptable design ensures consistent results across a wide range of packaging formats and product geometries.

Equipped with the option of either a fixed dispensing beak or a pivot beak, the 452C easily adjusts to different labelling requirements, maintaining accuracy and stability throughout the process. Compact yet powerful, it integrates seamlessly into existing production lines and is well suited for applications such as food trays, clamshells or punnets, where reliable top labelling and professional presentation are essential.

Through application testing and system commissioning, Result Group delivers the HERMA 452C ready to run. Our team ensures each system is tailored to your production needs, maximising accuracy, efficiency, and compliance.

Label from underneath without turning the product.

The HERMA 552C is designed for efficient and hygienic base labelling, applying labels directly via the conveyor system without the need to turn or manually handle products. This streamlined approach helps protect product integrity while supporting high throughput production environments.

Featuring a fixed dispensing beak and reliable label detection, the 552C delivers consistent, accurate label placement at high line speeds. Its compact, robust design allows for easy integration into existing lines, making it particularly well suited to food production and ready meal applications where cleanliness, efficiency and repeatable performance are critical.

Result Group streamlines the integration of the HERMA 552C into your production line, adding vision checks, print modules, and full traceability options where required. We deliver not just the machine, but a complete solution tailored to your quality and compliance needs.

Top and bottom labelling from one compact, flexible system.

The HERMA 652C combines two applicators in a single compact unit, enabling simultaneous top and bottom labelling in one pass. Each applicator can also operate independently, offering maximum flexibility across a wide range of product formats.

Built on HERMA’s modular design, the 652C supports quick and simple changeovers, helping minimise downtime. Its precise, reliable performance makes it an efficient solution for ready meals, bakery, and produce packaging lines where speed, accuracy, and versatility are essential.

Backed by our engineering expertise, Result Group ensures seamless integration of the HERMA 652C into your production environment. From coding integration to line optimisation, we deliver maximum uptime and efficiency.

Advanced three-faced labelling for demanding production environments.

The HERMA 752C is a compact, high performance wrap labeller designed for secure C and D-wrap labelling, making it ideal for hygiene critical production environments. Its stainless steel design supports the application of a single label across three or four sides in one pass, using precise dispensing via the HERMA 500 applicator.

Tool free adjustments enable quick changeovers for different product sizes, while the split conveyor ensures stable and reliable multi side labelling. Optional features such as thermal transfer printing, extended conveyor lengths and large diameter label unwinders make the 752C a versatile solution for food and FMCG manufacturers seeking efficient and professional pack presentation.

Food & beverage – sauces, condiments, dairy, bottles, jars, specialty containers

Home & personal care – detergents, shampoos, conditioners, lotion bottles

Industrial & chemical – automotive products, cleaners, maintenance goods

Nutraceuticals & pharmaceuticals – complex bottle shapes requiring precise multi panel labelling

Result Group supplies the HERMA 752C fully configured to meet your production and compliance needs. From integrated printing systems to advanced vision inspection for label accuracy, we deliver dependable, end-to-end performance for complex multi side labelling. With local installation, training, service, and consumable management, we ensure your packaging line stays fast, accurate, and retail ready.

Reliable high precision, high speed wrap-around labelling

The HERMA 152E is a compact, efficient wrap-around labelling machine designed for cylindrical applications such as bottles, jars, tubes, and vials. Created for businesses needing reliable labelling performance without complexity, the 152E provides consistent, accurate wrap-around application at speed. As part of the HERMA E Series, it offers essential functionality backed by trusted German engineering, making it an ideal choice for larger production lines.

With fast, tool free adjustments and a simplified operator interface, the 152E handles variations in product geometry with ease – without the need for change parts. Its streamlined design, small footprint, and dependable performance result in a smooth, stable wrap-around process that delivers professional packaging quality every time.

Result Group supplies the HERMA 152C Standard fully configured to meet your line requirements. From integrated coding solutions to vision inspection for label accuracy and compliance, we deliver end-to-end reliability for your wrap-around applications. With local installation, training, service, and ongoing consumable management, we make sure your packaging line stays compliant, efficient, and retail ready.

High performance labelling with a space saving footprint.

The HERMA 362 E is a compact front-and-back labelling system that combines the robust build quality of the M Series with the flexibility of the C Series. Designed with an open frame layout, it delivers precise and reliable labelling while minimising footprint, making it well suited to space-limited production lines.

Engineered for versatility, the 362 E supports a wide range of product shapes and sizes and allows quick, tool free adjustments for efficient changeovers. Its durable construction ensures consistent performance in demanding production environments, while maintaining the accuracy and stability required for high quality front and back label application.

Result Group supplies the HERMA 152C Standard fully configured to meet your line requirements. From integrated coding solutions to vision inspection for label accuracy and compliance, we deliver end-to-end reliability for your wrap-around applications. With local installation, training, service, and ongoing consumable management, we make sure your packaging line stays compliant, efficient, and retail ready.

Secure. Accurate. Built for tamper-evident labelling.

The HERMA 362E TE is a tamper-evident variant of the proven HERMA 362E two-side labelling platform, designed specifically for the application of security seals. Ideal for folding cartons, pharmaceuticals, nutraceuticals, and other regulated packaged goods, it ensures precise and consistent seal placement on both sides of the pack.

Building on the compact, flexible design of the 362E series, the 362E TE delivers reliable performance in space-constrained production environments while meeting strict compliance and quality requirements. Its robust construction and accurate label application help protect product integrity, enhance consumer trust, and support regulatory standards.

Pharmaceutical folding cartons requiring tamper-evident sealing

Healthcare and OTC medicine packaging

Regulated products requiring carton integrity and consumer safety

Folding boxes with side flaps requiring seal labels

High speed packaging lines with inspection and reject requirements

Manufacturers needing flexible carton sizes and fast changeovers

Result Group supplies the HERMA 362E TE fully configured to your carton sizes, security requirements, and compliance standards. We provide complete integration with printers, vision inspection, serialisation, and downstream tracking systems to ensure a validated, audit ready solution. With local technical support, spare parts, operator training, and ongoing service, we ensure your tamper-evident labelling process remains reliable, efficient, and fully compliant.

Pharma-grade precision for cylindrical packaging.

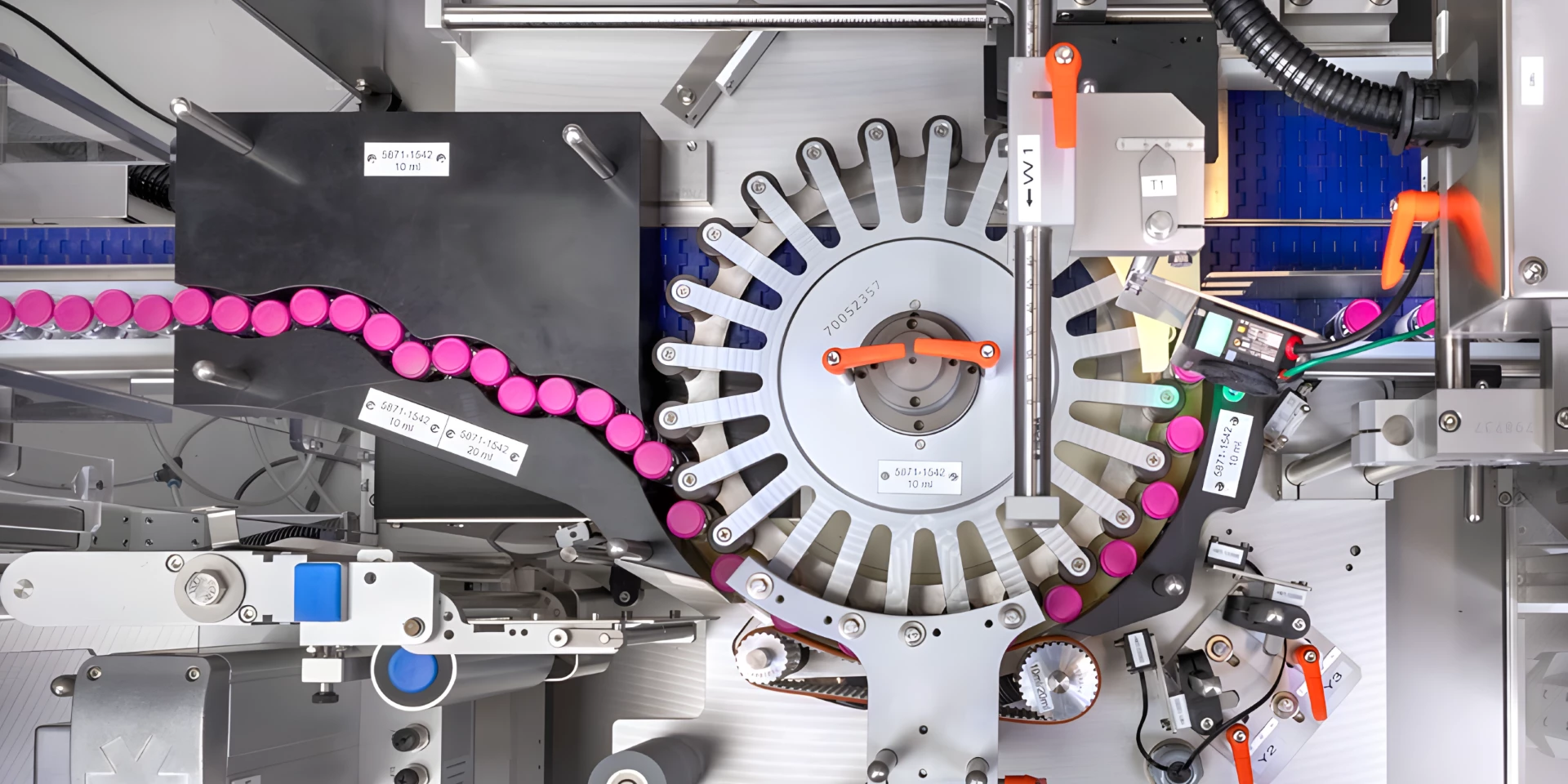

The HERMA 132M / HERMA 040M are high performance wrap-around labelling systems designed for precise and reliable labelling of cylindrical products. Available in two configurations, the HERMA 132M delivers continuous high speed labelling while the HERMA 040M, with its clocked starwheel, offers extremely precise labelling, making it ideal for longer or low-height labels.

Built on a compact, modular design using standard components, these machines offer excellent cost efficiency, fast changeovers and flexible configuration to suit a wide range of applications. Proven in pharmaceutical and regulated environments, the HERMA 132M / 040M combine robust engineering, advanced control and inspection options, and high safety standards to deliver consistent, high quality wrap around labelling in demanding production settings.

Result Group supplies HERMA 132M / 040M systems validated for pharma compliance, including installation, serialisation, and printer/camera integration for complete traceability.

Dual-sided accuracy in a modular, high-speed system.

The HERMA 362M is a powerful, high-precision two-sided labelling system designed for products with challenging shapes. Capable of labelling at very high speeds, it delivers accurate and repeatable front and back labelling, even in continuous high-speed production environments.

Built on HERMA’s modular Master Series platform, the 362M combines robust construction with maximum flexibility. Two high performance applicators ensure high throughput, while optional centring devices enable precise label placement on complex or irregular product shapes. With quick format changeovers, comprehensive inspection and reject options, and the ability to convert easily to wrap-around labelling, the HERMA 362M is an ideal solution for manufacturers requiring speed, precision and uncompromising product quality.

Dual applicators for front and back labelling

High speed, precise labelling

Fast changeovers and flexible configuration

Printer and inspection system integration

Robust design for demanding environments

Personal care bottles and containers

Household and industrial cleaning products

Pharmaceutical and nutraceutical packaging

Result Group configures the HERMA 362 M for your exact needs, integrating printers and quality control systems with local support for compliance and performance.

Request the Brochure

Please complete the form below so we can share the most relevant brochure and supporting information.