Home »

Rotary High Speed Labellers

Precision labelling at unmatched speeds for high-volume production lines.

Home »

Precision labelling at unmatched speeds for high-volume production lines.

High speed precision labelling with maximum flexibility and control.

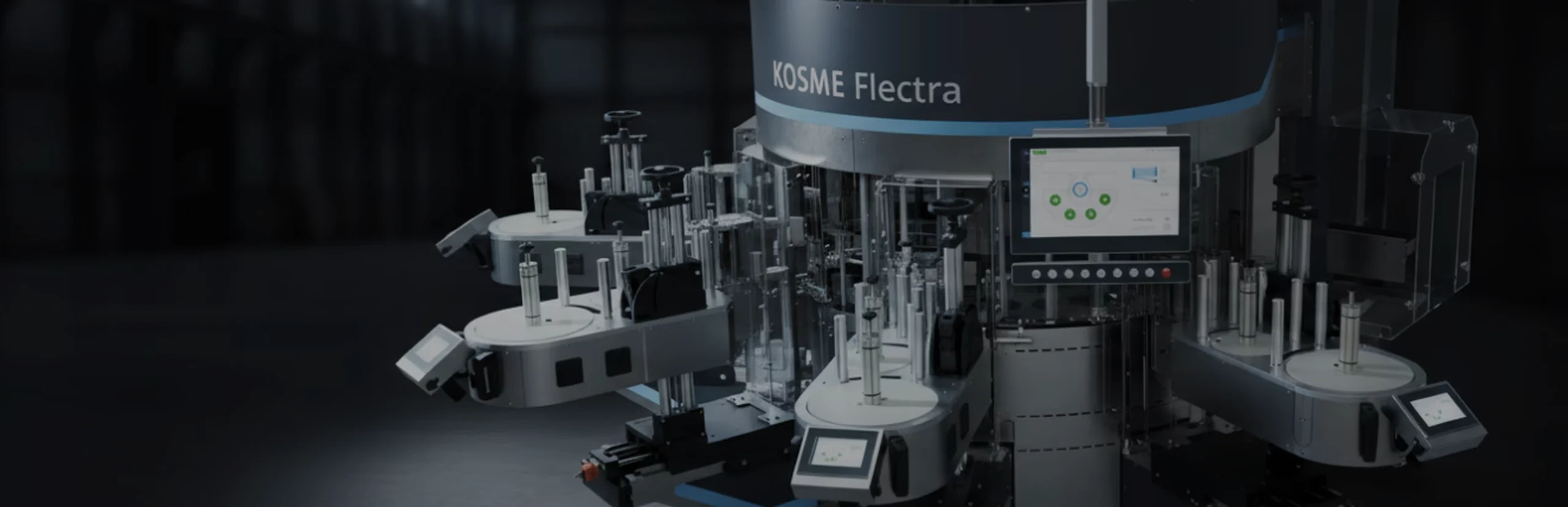

The Kosme Flectra is a new-generation labelling machine born from the collaboration between KOSME Italy and GERNEP GmbH. Designed for low to medium output ranges, Flectra combines high flexibility with outstanding precision, giving manufacturers a future ready platform that’s easy to operate, simple to reconfigure, and built for long term performance. With its compact omega shaped layout, modern HMI, and smart changeover concepts, Flectra delivers fast, reliable labelling while keeping operation and maintenance straightforward.

Beverage – water, soft drinks, juices, RTD beverages and premium spirits requiring high quality decoration

Food – sauces, dressings, condiments and specialty foods in a wide variety of container shapes

Home & personal care – shampoos, cleaners, detergents and cosmetics in shaped bottles

Private label and co packing – sites running multiple SKUs, formats and label types on shared assets

Brand owners upgrading legacy equipment – operations looking to move to a flexible, modular platform without sacrificing speed or accuracy

Result Group supplies the Kosme Flectra configured to your exact line requirements – from choosing the right combination of self-adhesive and wet glue units to integrating cameras, coding, and inspection systems. Our team supports layout design, installation, commissioning, and operator training to ensure a smooth start up and fast changeovers from day one. With local service, spare parts, and ongoing optimisation support, we help you get the most from your Flectra investment and keep your labelling operation efficient, flexible, and future ready.

Precision. Flexibility. Engineered for premium wrap-around results.

The Kosme Ultrareel is a high performance wrap-around labelling system designed to deliver exceptional precision, flexibility, and visual impact. In a market where purchasing decisions are driven by packaging appearance, Ultrareel ensures your product stands out with perfectly applied labels, even as consumer demands for information and decoration continue to grow.

Engineered for cylindrical and specially shaped containers, Ultrareel combines accurate container positioning with a reliable hotmelt gluing system to achieve seamless wrap-around results at speed. Tailored to meet the diverse needs of brand owners, contract packers, and high quality beverage and food producers, it delivers consistent performance, clean operation, and a premium finish every time.

Steel glue roller

Adjustable glue scraper

Precise and efficient adhesive application

Result Group supplies the Kosme Ultrareel fully configured to your container formats, label materials, and production requirements. Our team supports machine selection, hotmelt optimisation, installation, integration with coding and inspection systems, and full operator training. With local service, spare parts, and ongoing technical support, we ensure your Ultrareel runs reliably, delivers premium wrap-around presentation, and keeps your line performing at its best.

Efficient. Precise. Purpose built for cold glue labelling.

The Kosme Flexa Unicol is a high performance cold glue labelling system engineered for precision, efficiency, and versatility. Designed for producers seeking reliable decoration at high speeds, Flexa Unicol applies cut-and-stack paper labels with exceptional accuracy — delivering a clean, premium finish at a competitive operational cost.

Cold glue remains one of the most economical and visually consistent labelling methods, especially for high volume beverage and food applications. Flexa Unicol builds on this foundation with modern engineering, stable container handling, and excellent label control. Whether used for front, back, wrap-around, or multi panel applications, it ensures smooth production, quick format changeovers, and long term reliability.

Beverage – beer, cider, spirits, wine, soft drinks, RTDs

Food – sauces, spreads, oils, condiments, and pantry goods

Premium paper label brands seeking a traditional, high quality finish

High volume production lines requiring cost effective, reliable decoration

Producers needing multi panel or wrap-around paper labelling

Result Group supplies the Kosme Flexa Unicol customised to your production needs, including label format, glue system configuration, and bottle handling requirements. We support you through layout planning, installation, commissioning, and full operator training to ensure optimal cold glue performance from day one. With local service, spare parts, and technical expertise, we help you maintain consistent labelling quality and keep your line running efficiently.

Versatile. Efficient. Designed for multi technology labelling.

The Kosme Flexa Combicol is a highly flexible combined labelling system engineered to integrate multiple labelling technologies into one efficient platform. Ideal for producers managing diverse product portfolios, Combicol allows cold glue, hotmelt, and self-adhesive labelling technologies to operate from a single machine base — maximising versatility while minimising changeover effort and line footprint.

Designed for medium to high output environments, Flexa Combicol handles a wide variety of bottle formats and label styles with precision. Its modular configuration, stable container handling, and advanced glue and self-adhesive units ensure premium label presentation regardless of label material or application method. For brands and co-packers seeking future proof flexibility, Combicol provides an unmatched multi technology solution.

Result Group supplies the Kosme Flexa Combicol configured to your exact production requirements, including the optimal combination of cold glue, hotmelt, and self-adhesive stations. Our team supports machine specification, line integration, installation, and operator training — ensuring seamless operation from day one. With local service, spare parts, and long term technical support, we help you maintain consistent decoration quality and maximise the value of your combined labelling solution.

Request the Brochure

Please complete the form below so we can share the most relevant brochure and supporting information.