Home »

Shrink Sleeve

Full-surface labelling that boosts shelf appeal and delivers secure, premium product presentation.

Home »

Full-surface labelling that boosts shelf appeal and delivers secure, premium product presentation.

Compact, affordable, and designed for small scale automation.

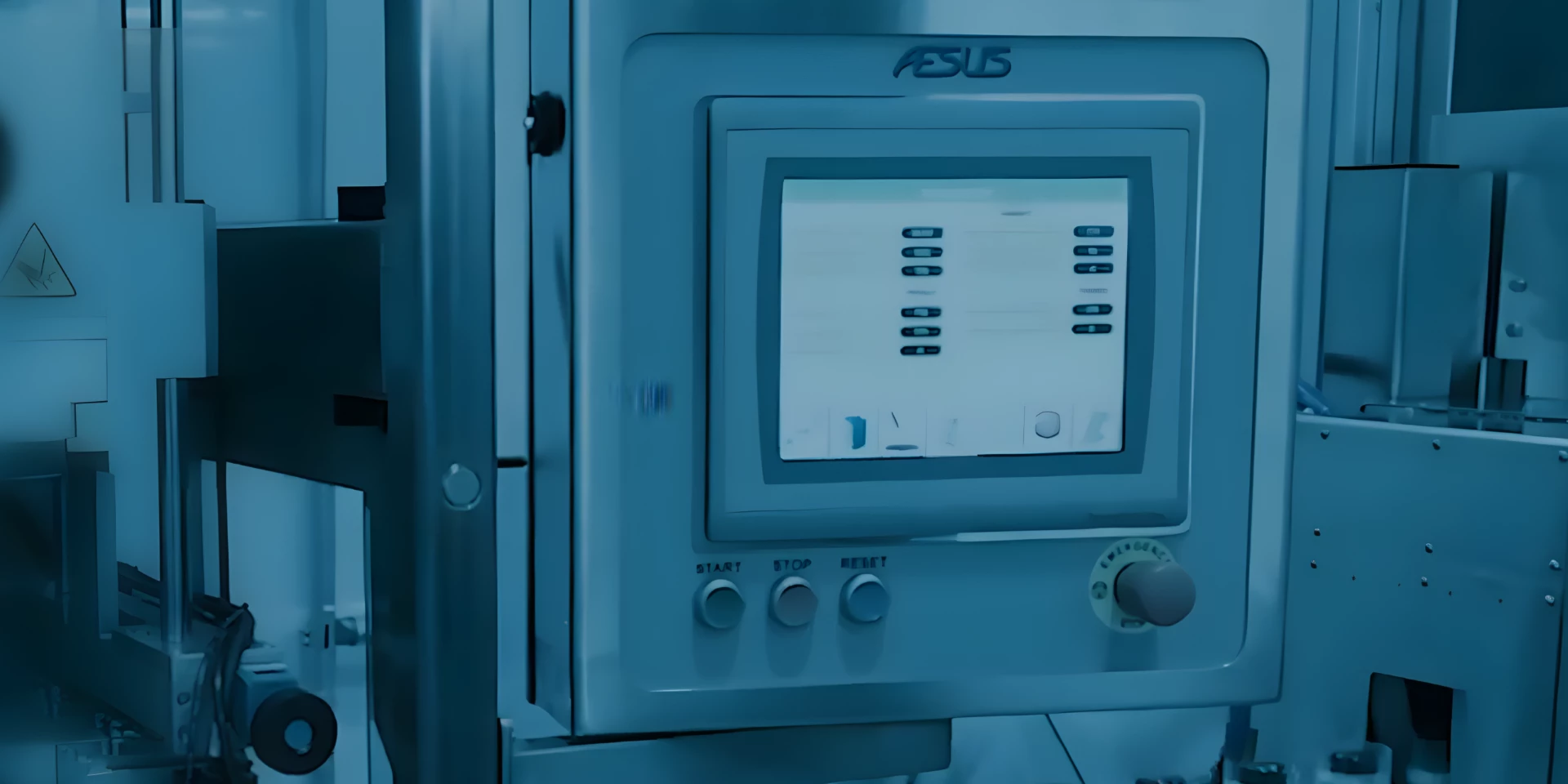

Designed for small operations, pilot lines, or artisan producers, the AESUS Economy Sleeving model provides accurate sleeve placement at a budget friendly price point. Compact, reliable, and easy to operate, it’s the perfect first step into automated sleeving, delivering consistent, high quality results for tamper-evident neck bands and low speed full body applications.

Compact footprint for easy integration in small scale production lines

Accurate and repeatable sleeve placement for consistent quality

User friendly design for quick setup and operation

Handles both neck band and full body sleeve applications

Cost effective solution ideal for first time automation

Start ups and artisan producers seeking affordable automation

Food, beverage, and cosmetic products in small batches

Pilot or limited production runs requiring professional presentation

Result Group provides complete support from consultation to installation, ensuring seamless integration and reliable operation. Our team assists with setup, training, and after-sales service to help small producers confidently automate their packaging process and achieve a premium, shelf ready finish.

Reliable, precise, and built for growing production demands.

Engineered for expanding operations, the AESUS Intermediate Sleeving model delivers accurate, high quality full body sleeve application with increased throughput. Designed for integration into standard conveyor systems, it provides smooth, consistent performance and a professional finish across a wide range of container types – ideal for food, beverage, and personal care packaging.

Mid speed performance for growing production lines

Consistent, high quality sleeve placement on various container shapes

Seamless integration with existing conveyors and packaging systems

User friendly interface and tool less changeovers

Durable construction for long term reliability and low maintenance

Medium volume food, beverage, and personal care production

Full body branding and tamper-evident sleeving

Businesses scaling from pilot to mid tier manufacturing capacity

Result Group offers full integration support, operator training, and tailored line solutions to ensure optimal performance and efficiency. Whether upgrading from entry level automation or expanding production capacity, our team ensures a smooth transition with consistent, professional results every time.

Fast, precise, and engineered for large scale, high output production.

Built for demanding, high volume environments, the AESUS High-Speed Sleeving model delivers exceptional accuracy and performance at speeds of up to 600 containers per minute. Designed for full-body, combo, and tamper-evident applications, it combines advanced servo driven control with intelligent automation to ensure perfect sleeve placement, even at the highest line speeds.

Handles up to 600 containers per minute with exceptional precision

Advanced servo driven sleeve application for consistent results

Multi sleeve capability for complex product configurations

Built for 24/7 commercial operation and seamless integration

Robust, stainless steel construction for durability and reliability

High speed beverage, pharmaceutical, and FMCG production lines

Full body, combo, and tamper-evident sleeve applications

Large scale operations requiring high accuracy and continuous throughput

Result Group delivers comprehensive support for high speed systems, from integration and setup to ongoing service and optimisation. Our engineering expertise ensures smooth performance, maximum uptime, and consistent, professional results, even in the most demanding production environments.

Request the brochureConsistent, high quality shrink performance for every sleeve type.

The AESUS Heat Tunnel delivers precise, uniform shrink performance across all sleeve materials and container shapes. Available in both steam and dry heat configurations, it ensures a smooth, bubble-free finish for tamper-evident, full body, or combo sleeves. Engineered for efficiency and reliability, the system integrates seamlessly with all AESUS applicators to create a complete, professional sleeving solution.

Compatible with all AESUS sleeve applicators

Available in steam or dry heat configurations

Even heat distribution for consistent, wrinkle free shrink results

Adjustable temperature and airflow for precise control

Compact, durable design for reliable long term operation

Food, beverage, cosmetic, and pharmaceutical packaging lines

Full body, partial, or tamper-evident sleeve applications

Products requiring a smooth, high quality shrink finish

Result Group provides full integration support for AESUS Heat Tunnel systems, ensuring optimal performance and energy efficiency. From selecting the right tunnel type to commissioning and maintenance, our team helps deliver a flawless finish that enhances both product quality and shelf appeal.

Request the Brochure

Please complete the form below so we can share the most relevant brochure and supporting information.