Home »

Barcode Verifier

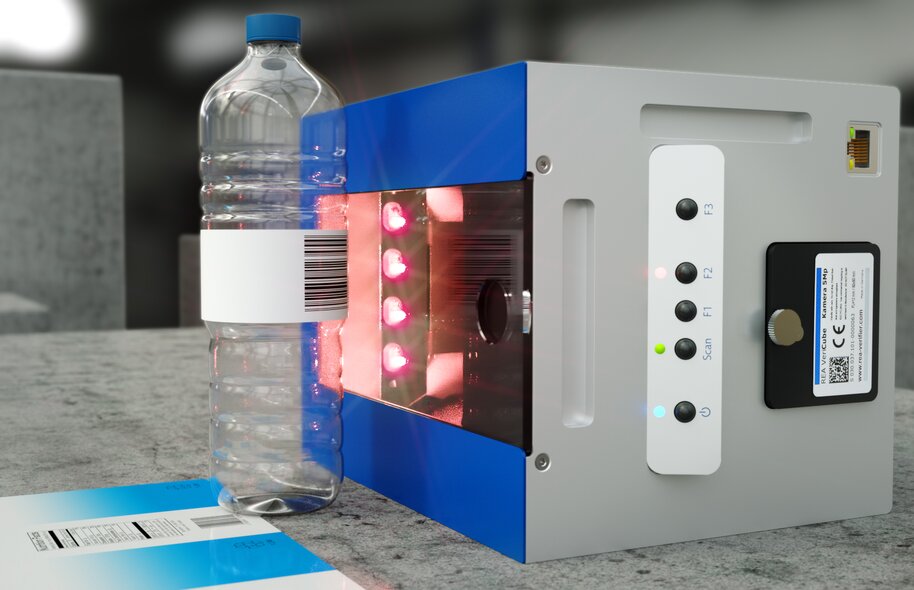

Rea Verifier – Inline Barcode Quality Assurance

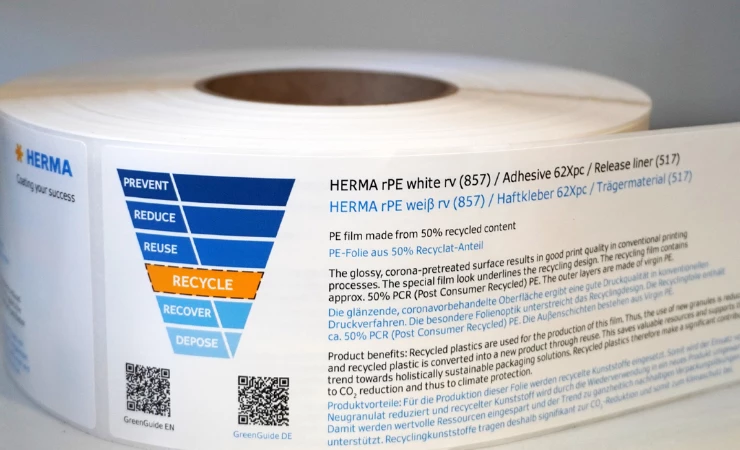

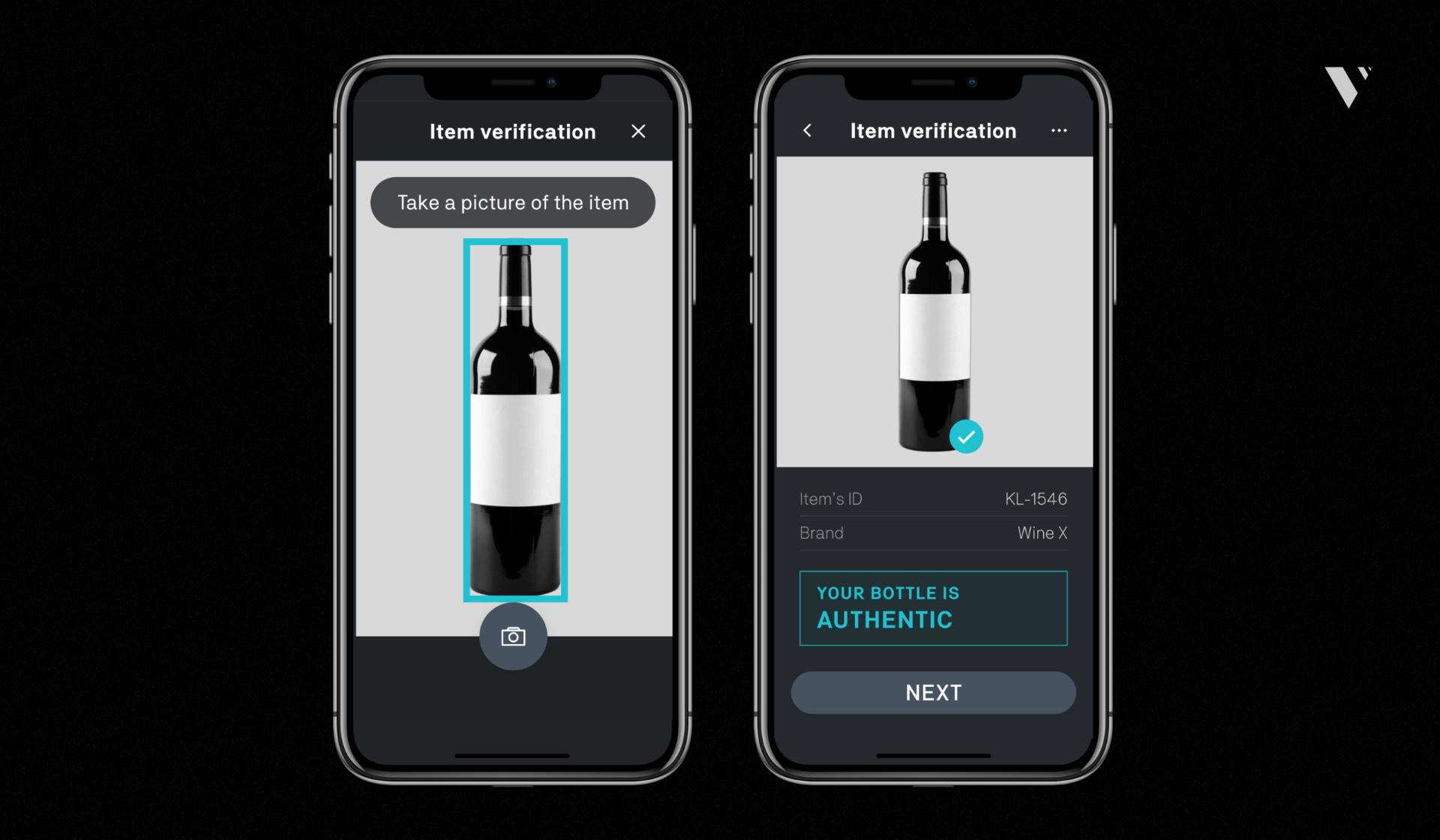

The Rea Verifier is a high precision barcode verification system designed to assess both 1D and 2D codes. It instantly grades and validates each barcode against global ISO/IEC standards. This ensures only compliant, scannable codes reach packaging, eliminating costly reprints and avoiding supply chain or retail scanning failures.