Packaging

Navigating Compliance: What APCO’s Soft Plastics Labelling Change Means for Brands in July 2025

As of 1 July 2025, updated requirements from the Australian Packaging Covenant Organisation (APCO) are now in effect. Under the new guidelines, all mentions of REDcycle and Return to Store must be removed from soft plastic packaging, point of sale materials, and digital assets by ARL program participants.

This change reflects the growing focus on transparency and accuracy in environmental labelling, especially following the suspension of REDcycle’s collection program. For brands with pre printed packaging still in circulation, the directive has introduced a challenging question: how to meet compliance without generating unnecessary waste or triggering costly production delays?

A Practical Challenge for Brands

In many cases, product packaging with REDcycle branding was printed months in advance, forming part of planned inventory or already sitting in warehouses and retail stores. Disposing of that stock outright would be costly, not only financially, but environmentally.

This has led many businesses to explore low impact alternatives to full reprints, particularly for high volume product lines where time and continuity are critical.

Overlabelling: A Sustainable Compliance Solution

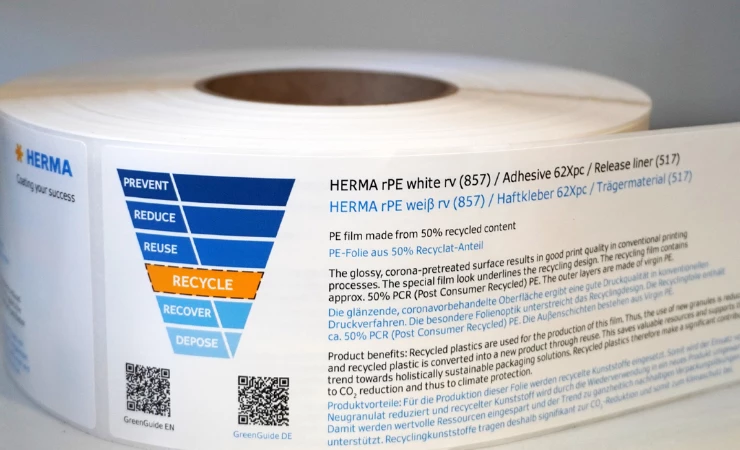

One proven method that has gained traction in recent months is overlabelling. It involves applying food grade, self-adhesive corrective labels directly onto existing packaging, covering the outdated REDcycle or “return to store” messaging.

At Result Group, we’ve been supporting brands through this transition by providing a fully managed overlabelling service designed specifically for high- speed FMCG environments.

Here’s how it works:

- Targeted Correction: The overlabelling process pinpoints the non compliant section of each pack and applies a precise, high adhesion label to conceal it

- Food Grade & Compliant: Labels meet food safety and packaging standards and are engineered for durability, ensuring full compliance on shelf

- Minimal Disruption: Using a custom built handling system, labels are applied at speed and with accuracy, so production lines can continue operating with minimal changes

- Waste Avoidance: Brands avoid disposing of usable packaging stock, aligning with sustainability goals while meeting legal obligations

Why It Matters Now

As APCO begins auditing on shelf compliance and works with the ACCC to enforce the new standards, the window for inaction is narrowing. Brands that take early steps to address their packaging without waste or reprint delays, are better positioned to maintain consumer trust and avoid potential regulatory complications.

More broadly, this moment signals a shift in how packaging regulations are enforced and how brands need to be able to adapt. Overlabelling is not just a workaround, it’s a demonstration of agility and accountability in action.

Moving Forward

The updated APCO directive is a reminder of the fast changing nature of packaging compliance. For businesses, it’s an opportunity to approach packaging decisions with both practicality and purpose embracing solutions that are not only compliant but also reduce environmental impact and protect brand continuity.

If your business is still working through what this change means or how to respond efficiently, Result Group continues to support brands with end-to-end overlabelling services built around speed, compliance, and sustainability.

Learn more about our process here https://resultgroup.com.au/value-added-creative-packaging/export-food-labels/