C Series Label Applicators

HERMA 152C – Wrap around label applicator

HERMA 152C – Wrap around label applicator

The HERMA 152C Standard and the 152C Prisma – a label applicator range that masters every challenge of wrap-around labelling, even when confronted with tricky labelling tasks. Flexibly designed to accept an optional printing unit (hot-foil printing for instance) as well as motorised unwinders and rewinders for a higher output capability. The tested HERMA 152C Prisma technology guarantees precise labelling, even if the product has minor geometric variations. Spiral misalignment is practically eliminated and labelling in orientation, including twin labelling, is no longer a problem. The roller-type prism can be adjusted simply by means of a scale for different product diameters – additional change parts are now a thing of the past.

HERMA 362C – Side label applicator

A compact, sturdy labelling machine that works without change parts. The advantage: quick, straightforward and flexible retooling for precise side labelling. This system is distinguished by its outstanding production efficiency in combination with low investment costs. A synchronous top belt can be used to stabilize the products. The modular system can be fitted with either one or two HERMA 400 applicators equipped with a pivot beak. A printer can be installed if required to allow for optional label overprinting, such as the date of manufacture or a sell-by date.

HERMA 452C – Top label applicator

Compact, reliable, state-of-the-art technology for top labelling of a wide range of products and food packaging, etc. This label applicator machine can be supplied either with a fixed dispensing beak and a sprung-loaded application roller or with a pivot beak. The pivot beak allows for the precise linear labelling of objects with large dimensional tolerances, irregularities or recesses (such as margarine packs etc).

HERMA 552C – Base label applicator

HERMA 552C – Base label applicator

The proven solution for base labelling of products. This label applicator is equipped with a fixed dispensing beak and a label recognition unit. Label application is taken care of by the conveyor belt in order to ensure maximum efficiency. Products that are already transported in the correct position (in a production line, for instance) no longer need to be turned over for labelling. The label applicator can be retracted from under the conveyor belt in order to change the label roll.

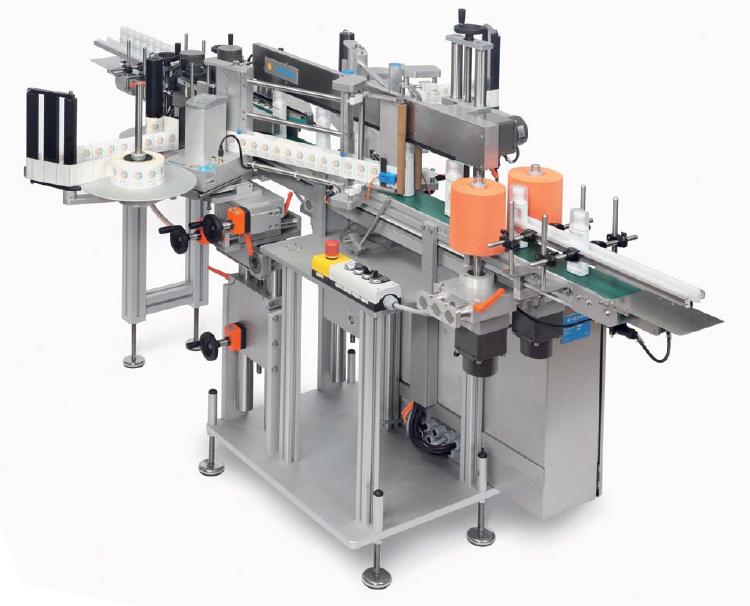

HERMA 652C – Top and base label applicator

Top and bottom labelling in one cycle – that is what makes the 652C so particularly efficient and productive. It retains all the benefits of top and bottom labelling machines, but remains compact and highly flexible when used with two label applicator units. It delivers the best labelling results and can also be used to provide top or bottom labeling only if necessary. The 652C sets new benchmarks in quality, precision and efficiency, and can also be customized based on our modular system. Naturally, it can also be adjusted to different product formats with ease.

Top and bottom labelling in one cycle – that is what makes the 652C so particularly efficient and productive. It retains all the benefits of top and bottom labelling machines, but remains compact and highly flexible when used with two label applicator units. It delivers the best labelling results and can also be used to provide top or bottom labeling only if necessary. The 652C sets new benchmarks in quality, precision and efficiency, and can also be customized based on our modular system. Naturally, it can also be adjusted to different product formats with ease.

HERMA 752C – Top, front face and base label applicator

The HERMA 752C automatically applies in one pass, a three panel label to the top, front and base on a wide range of packs and trays including fresh meat, produce and ready meals. The HERMA 752C facilitates quick changeovers in the very busiest of production environments. This label applicator system is suitable for all environments and when not applying three panel labels the 752C can be utilised for standard top labelling operations.

The HERMA 752C automatically applies in one pass, a three panel label to the top, front and base on a wide range of packs and trays including fresh meat, produce and ready meals. The HERMA 752C facilitates quick changeovers in the very busiest of production environments. This label applicator system is suitable for all environments and when not applying three panel labels the 752C can be utilised for standard top labelling operations.

Switch to: H500 Series E Series M Series