Choosing an industrial inkjet printer is a big decision. Inkjet coding and marking is a small but essential part of the production line, and can have a significant impact on the success of your business.

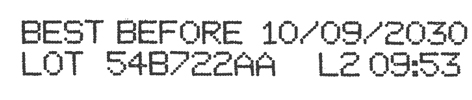

Most manufacturers rely on CIJ printers for coding. Whether for legal reasons, for supply chain batch identification or simply for customer information, coding information often needs printing directly onto products or packaging. Industrial inkjet printers are the key to this – and the key to making the right buying decision is to take into account the following five important points.

1. Ink should never dry out on the print head!

There is one problem that has always concerned users of industrial inkjet printers. Because the ink has to dry quickly, it can also dry out when coding is paused. This clogs the nozzle and requires a laborious and time-consuming cleaning and rinsing operation before production can start up again. Not only that, the first few prints after cleaning can be of a lower quality. But how to solve the problem when the ink is designed to dry instantly on products and packages?

One of the industry’s most convincing answers came in the form of Leibinger’s Sealtronic printhead technology. The way Sealtronic works is wonderfully simple. The ink return line, or gutter, is automatically retracted into the nozzle when coding stops and the printer is switched off, creating a hermetically sealed, air-tight circuit. Most other printers leave the return line open, exposing the ink to the air, allowing it to dry and clog the nozzle.

With the nozzle seal in place, the ink stream remains pressurized. When you want to re-start coding, the ink gutter moves into its open position and within seconds, the system is ready to print. Equipped with the automatic Sealtronic nozzle sealing system, Leibinger inkjet printers are coding again in just a few seconds and always start with a clean print. It also offers the advantage of using less consumables.

2. A continuous inkjet printer needs to fit into your production line – not the other way around

All production lines are different, and require different solutions. This means you may need your inkjet industrial printer to be installed in a very small space, or for the print head to be installed at a non-standard angle. There is no single way of doing it, so you should look for a printer that is flexible enough to fit in with the way you work. Also, ensure that it provides all the connections you need to ensure easy integration into your existing production systems.

3. Choose the nozzle size and speed you need on your CIJ printer

It is also true that production lines run at different speeds and have different legibility requirements, requiring both large character and small character printing options. Barcodes, text characters and logos need to be legible and, if you are printing on smaller items, such as electronic components, you may need a small character inkjet printer with a finer nozzle instead of a larger nozzle. An inkjet barcode printer with a 35µm nozzle, for example, enables high-quality inkjet coding at a very small font size.

If your coding applications require faster printing, make sure you choose CIJ solutions that can keep up. Some cable printing solutions, for example, can operate at up to 1,000m every minute.

4. A continuous printer needs to be tough

Industrial printing systems need to be durable. Production environments, such as food, timber yards or flour mills, can be extremely dusty or subject to high hygiene regulations. Such conditions require a stainless steel housing without plastic elements and often a pressurized printhead – which ensures that dust particles are not able to interfere with printing.

Industrial printing systems need to be durable. Production environments, such as food, timber yards or flour mills, can be extremely dusty or subject to high hygiene regulations. Such conditions require a stainless steel housing without plastic elements and often a pressurized printhead – which ensures that dust particles are not able to interfere with printing.

Many food producers need to adhere to stringent hygiene requirements, which frequently involves washing down equipment, including printers. It may therefore be necessary to look for industrial inkjet printers with IP65 protection in order to withstand the rigours of the daily wash-down.

5. A continuous inkjet printer must be simple to use

While your production line may be largely automated, manual intervention is often required – for example, when the information printed on each product has to be manually altered. Make sure that the printer you choose has an easy-to-use display screen, differentiation between administrator access and production employee access, and that the manufacturer provides training. Industrial marking software, for example, should be WYSIWYG – enabling users to see precisely how the final print will appear.

Source: Article courtesy of www.leibinger-group.com

You must be logged in to post a comment.