- Don’t Recycle the liner – REMOVE IT!

- Remove waste from landfill

- Suitable for any variable print technology

- Custom print on conventional label presses

These days, both consumers and brand owners are aware of the importance of sustainability, environment protection and climate change. Industries by and large, driven by government regulations are reviewing production processes and re-designing packaging with the aim of reducing resource consumption and waste. “Given the growing need for sustainable methods and products in both retail and shipping industries, it’s no surprise that linerless technology has seen a growth in popularity,” said Michael Dossor, Group General Manager at Result Group. “Result Group is committed to offering packaging and materials that are more sustainable and tackle plastic waste and have partnered with like-minded suppliers to address one of the biggest economic and industrial challenges.” Already offering linerless technology for finished products, we have now extended our linerless solutions to the labelling of cartons and shippers.

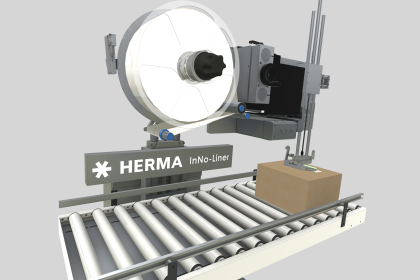

Pooling its expertise across all of its divisions, HERMA has developed the InNo-Liner system – the first of its kind to cater for the requirements imposed by shipping labels. The InNo-Liner system is not only a cost-cutting game changer from the perspective of logistics and shipping, but also actively contributes to protecting the environment as it removes thousands of square meters of siliconised paper liner from the market and the waste disposal chain. The holy grail of sustainability is to remove an item before even having to recycle it and HERMA’s InNo-Liner delivers just that, no problematic silicon release liner!!!

Hanes, the owner of such brands in Australia as Bonds, Sheridan, Champion and Berlei has already committed to the new HERMA Linerless technology as part of its 2030 global sustainability goals that include addressing the use of plastics and sustainable raw materials in products and packaging. The HERMA InNo-Liner system from Result Group combined with the linerless labels, supplied by Label Manufacturers Australia (Part of the TMA Group), will drastically minimise the climate-relevant CO2 footprint of labels (no liner) and a great amount of waste is going to be avoided.

Kate Appleby, National Sales Manager (Labels) of Label Manufacturers Australia (LMA) said that most companies focus on packaging that is used and discarded by the consumer often omitting the warehouse and distribution space where tons of silicone paper is discarded each day. “The HERMA InNo-Liner technology was the perfect solution for Hanes to adopt at the back end of their supply chain. It will help create sustainable value for the company, stakeholders and communities. The bottom line was a strong ROI when replacing conventional label materials and machinery currently installed. Savings in the material itself, as well as removing waste disposal and a host of other measurable benefits”, said Kate Appleby.

The HERMA linerless system is designed to apply labels to the side or top of outer shipper cartons or boxes of different heights that are fed to the applicator in any sequence. The InNo-liner system transfers the initially non-sticky label to a tamp pad, which is equipped with a box height sensor and a linear dosing unit. A water activation unit performs a transverse motion underneath the label where it activates the adhesive with a highly consistent spray of micro-atomised water. Then the linear transfer unit automatically moves the tamp pad, with the activated label to the required labelling height for the next case in the line.

This is all done at the same speed of a traditional Print and Apply Labelling system. “The key benefit of the system is that no coatings are placed on the surface of the face-stocks to aid in the unwinding of the stock on the applicators” says Michael Dossor, Result Group General Manager. “This means no negative impact is felt with variable printing, a key challenge with alternative Linerless systems and, standard Direct Thermal and Thermal Transfer materials can be used. There is simply no change to the way the cartons are recycled in current systems.”

The underlying principle is easy to understand and simple. It does not involve any solvents, heat or other activation media associated with possibly undesirable side-effects. For printing variable data on the labels, both thermal transfer and direct thermal options are available and labels can also be pre-printed in colour with conventional techniques.

The HERMA linerless technology complements our existing Ravenwood linerless technology for finished products. Result Group, in partnership with Ravenwood authorised label printers, Hally Labels, Label Force and Label Manufacturers Australia (LMA), are committed to assist brand owners meet their sustainability goals and deliver the type of eco-friendly packaging that consumers demand.

You must be logged in to post a comment.