- No major capital expense required.

- Won‘t slow your production output.

- More cost effective than any other closure.

Now more than ever, offering your customers a tangible reason to buy your product over your competitors, is a key factor in day-to-day consumer goods sales.

This coupled with packaging formats that are hard to open or not used for anything more than the trip home from the retailer, reduces the interaction consumers have with your brand.

This coupled with packaging formats that are hard to open or not used for anything more than the trip home from the retailer, reduces the interaction consumers have with your brand.

This has prompted many FMCG companies to look at introducing convenient Reseal, Reclose or Easy Open systems.

The challenge has been complex at every level from capital equipment to ongoing production usage and of course consumer acceptance. Well ….. no more!

Unique external value added processing enables us to either add a Reseal, Reclose or Easy Open feature to the packaging materials between the packaging printing and filling stage, or adding application technology to your existing filling or forming machinery.

A self-adhesive label applicator from HERMA or a tape application system from Sealstrip to apply the functional element to your film on the Vertical or Horizontal Flow Wrapper or even Vacuum Packaging System and Carton erector loader, combined with specially developed self-adhesive labels and Finger Lift Tapes delivers a solution that will have customers praising your packaging.

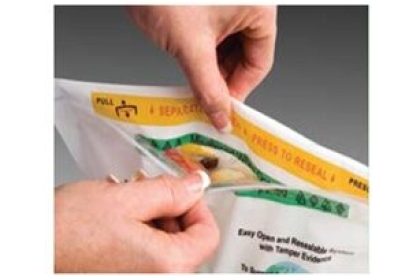

Systems such as Peel&Seal™, a simple resealable tape that acts as an easy fold over based reseal, to FreshPak™ – a true Easy Open, tamper evident and resealable packaging system, or BEND-SEAL™ – a memory based fold reseal device. These have been easily adapted to any type of pack and machinery to deliver a problem free, consumer friendly feature.

If you are currently using a mechanical type of press seal reseal, the savings in capital, production and materials have to be seen to be believed.

Pack functionality is not complicated when the right focus and expertise is applied, and we would be only too pleased to show you how it’s done.

You must be logged in to post a comment.