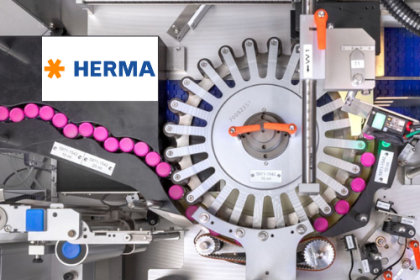

HERMA 132M HC sets the standard for performance, precision and reliability

This wrap-around labeler applies labels to cylindrical products with the utmost accuracy at highest performance. In order to satisfy the requirements of the healthcare industry – e.g. relating to audit trails, track & trace, and serialization – absolute operating reliability and process controls are especially important. Its modular design allows the machine to be adapted to its environment with great flexibility. In addition, ergonomic design, short setup times and simple format changes significantly enhance economic efficiency. The superfast wrap-around labeler is also available with a clocked starwheel for high-precision label application, and the labels can optionally be aligned with a salient product feature.

132M HC: Uncompromisingly fast and reliably effective

- Primarily designed for round pharmaceutical products, such as glass vials and the corresponding high batch sizes in the healthcare industry

- Wrap-around labeler 132M HC for healthcare products with a high-speed output of up to 400 products per minute

- High labeling speed with extreme precision thanks to the new HERMA 500, our high-performance applicator

- It is completely equipped for all healthcare tasks, including a selection of various printing and control systems, an patented automatic label return with cross check, as well as one of several possible product reject stations

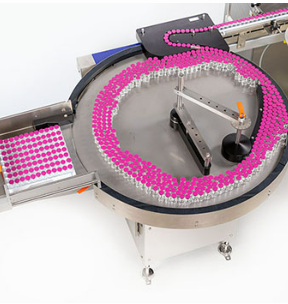

- New innovative HERMA rotary tables, electronic position indicators and format sets that can be exchanged without tools for fast format changes ensure maximum overall equipment effectiveness

- The 132M HC can be easily configured for numerous industry applications – even without printers and control systems in the version 132M

- Optionally available with the clocked starwheel in the version 040M HC that is exactly aligning the labels with a salient product feature

Flexibility in every line

Consummate ease of use facilitates speed and precision when setting up,re-equipping and making fine adjustments – even when confronted with rapidly changing product formats and batches. Thanks to its diverse application scope and modular design, the 132M HC is also well equipped to accommodate future productivity increases.

Reliability in every application

A variety of monitoring systems verify the presence of print, variable text and codes on the labels. And various sensors reliably check that labels have been applied to the products. Reject stations make certain that only verified labels and products are forwarded.

Versatility in design

Apart from the full-featured healthcare version, the machine can be configured for use in numerous other sectors – including without a printer and control system.

Assure efficiency

In order to balance the usual instabilities in the product flow, products can be buffered on a rotary table at the infeed or outfeed. This ensures the highest possible labeling efficiency. Additional magazine holders make it easy to feed products into the labeling process or remove them.

Individualize marking

Different printing systems can be integrated for marking pharmaceuticals, e.g. with batch number or expiry date. Checking systems for print and code verification ensure reliable product quality. The modular design is highly flexible and allows numerous individual equipment requests to be realized.

Avoid mix-ups

Thanks to the automatic reject of labels with missing or unreadable print or code, only well checked labels are applied to the products.

Minimize set-up times

With the continuously rotating starwheel of the 132M HC, up to 400 products can be labeled per minute – with the manufacturing precision and reliability typical of HERMA. In order to save time during changeover, format parts such as the starwheel can be changed without tools and with just a few simple steps.

Maximize security

UV sensors check the presence of the labels on the products and thus ensure reliable detection of all labels with luminophores on the products.

Ensure product quality

Thanks to the automatic rejection of products without labels and the cross-checking of the rejection, it is ensured that only well checked products leave the machine. Even the separation of products without labels is realized extremely smoothly on a reject conveyor.

You must be logged in to post a comment.